What Is Spot Color Printing for T-Shirts?

Ever had a t-shirt printed and the colors came out faded, blurry, or just not what you expected?

That usually means the wrong printing method was used for your design.

When it comes to bold logos, vibrant graphics, and accurate branding, there’s one method that stands out: spot color printing.

In this guide, we’ll break down what is spot color printing, how it works, and when it’s the best choice for your custom t-shirt orders.

Whether you’re printing for your business, a clothing brand, or a special event, understanding this method could save you time, money, and a lot of frustration.

Let’s get into it.

What Is Spot Color Printing?

If you're new to t-shirt printing, the term spot color might sound technical—but the concept is actually simple.

Spot color is a printing method where each color in your design is printed using a pre-mixed, solid ink. Instead of combining inks (like in CMYK or digital printing), every color is applied individually. That means the red you choose will look exactly like that same red across every shirt.

Designers often use the Pantone Matching System (PMS) to choose and communicate specific spot colors. This ensures your artwork looks consistent whether you're printing 50 shirts or 5,000.

It is also the go-to method when your design calls for:

Bold solid colors

Clean edges

Consistency across every print

It's especially useful for t-shirt orders that feature logos, text, or graphics in a limited number of colors.

How Spot Color Screen Printing Works

Now that the basics make sense, here’s a closer look at how spot color screen printing happens at Tee Vision Printing—from digital file to wearable art.

1. Artwork Separation

Everything begins with the design. The artwork is carefully broken down into its individual spot colors.

For example, if the graphic includes red, black, and white, each color is separated into its own layer. These layers will later be used to create the individual printing screens.

2. Screen Preparation

Once the color separations are finalized, the screens come into play.

Each spot color gets its own mesh screen. These screens are coated with a light-sensitive emulsion.

Then, using UV light, the separated artwork is burned onto the screen to create a stencil for that color.

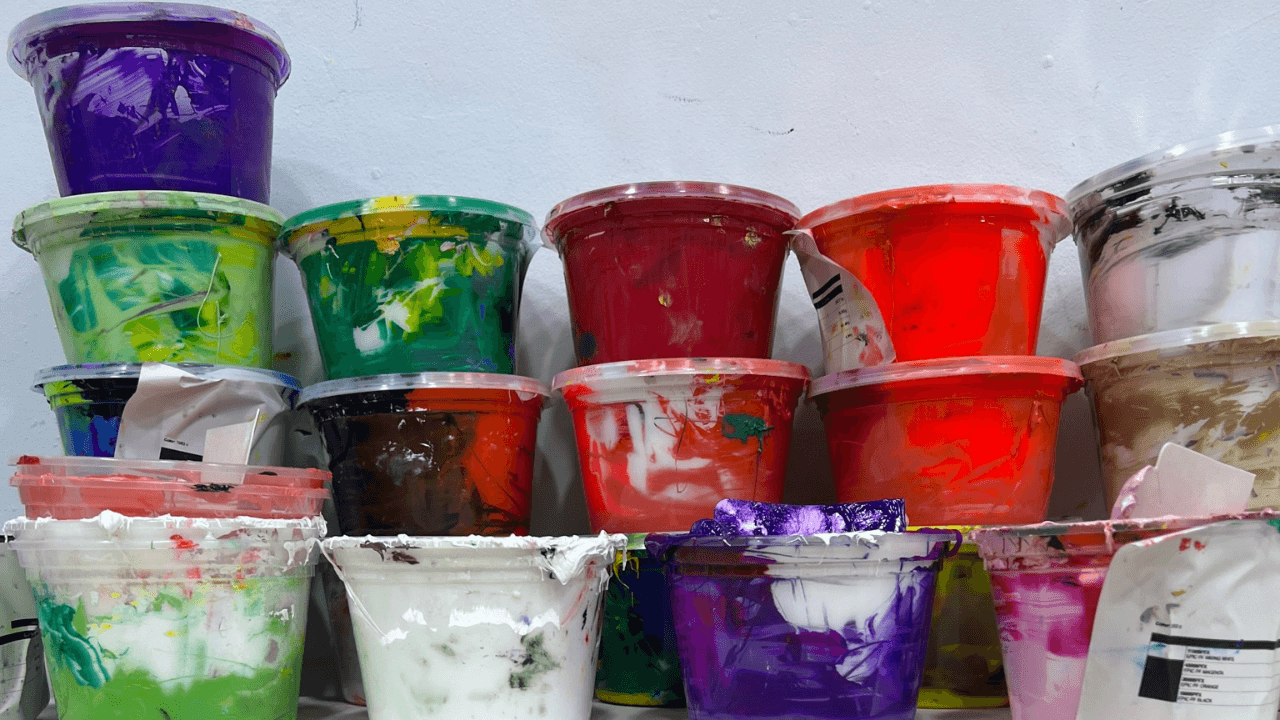

3. Ink Mixing

Accuracy matters—especially for branding.

That's why inks are mixed using exact Pantone Matching System (PMS) codes. This ensures that the printed colors match your brand’s specifications down to the smallest detail.

4. Printing

Now the real magic begins.

Each screen is loaded onto the press and aligned with precision. Using a squeegee, each ink color is pushed through its stencil onto the fabric. This layering process keeps lines sharp and colors perfectly in place.

5. Curing the Ink

After printing, shirts are sent through a high-temperature conveyor dryer.

This step cures the ink—locking it into the fabric so the print won’t fade, crack, or peel, even after multiple washes.

When Should You Use Spot Color Printing?

Not every t-shirt printing job calls for spot color, but plenty do.

Here are some situations where it’s the clear winner:

Brand Logos: If your company’s logo has specific colors that need to match your branding exactly, spot color screen printing delivers consistency every time.

Simple Designs with Few Colors: Spot color works best with designs using 1–4 solid colors. It’s clean, cost-effective, and reliable.

Printing on Dark Fabric: Want your white design to pop on a black shirt? Spot color has better opacity than CMYK or DTG, so your design won’t look washed out.

Bulk Orders: Screen printing has higher setup costs, but the per-shirt cost drops dramatically with larger quantities. So if you’re printing 50+ shirts, spot color is a smart choice.

Benefits of Spot Color Screen Printing

Let’s dig into why so many people choose spot color for their custom shirts:

1.) Perfect Color Matching

Want your red to always look like your red? Spot color nails color accuracy every time.

2.) Durability

Spot color prints can last for years. They don’t peel, crack, or fade easily—especially if you follow proper care instructions.

3.) Bold, Clean Designs

This method produces sharp lines and bold fills. No fuzzy edges or weird blending.

4.) Better on Dark Colors

Compared to CMYK or DTG, spot color stands out on dark shirts because the ink sits on top of the fabric, not within it.

5.) Scalable for Bulk Orders

Once the screens are made, we can print hundreds or thousands of shirts quickly and cost-effectively.

According to IBISWorld, the custom screen printing market is thriving, valued at over $1.8 billion in the U.S. alone in 2023. That’s a strong indicator that traditional methods like spot color screen printing remain popular and effective for high-volume, high-quality shirt orders.

Spot Color vs Other Printing Methods

Here’s how spot color stacks up against other methods like DTG, CMYK, or heat transfer:

DTG (Direct to Garment) is great for photo-style prints or full-color gradients but can lack vibrancy and durability on dark shirts.

CMYK printing mixes inks to create colors but can struggle with consistency, especially when printing brand-specific colors.

Heat transfer is decent for small runs or one-off shirts, but designs often crack or peel over time.

If your goal is solid, sharp, and professional-looking prints, spot color screen printing is still the top choice.

Why Choose Tee Vision Printing for Spot Color T-Shirts

At Tee Vision Printing, we’ve handled thousands of spot color screen printing jobs for clients across the country. Whether you're a startup clothing brand, a local business, or an event organizer—we know how to bring your designs to life.

Here’s what makes us different:

We use premium t-shirt brands like Bella+Canvas, Next Level, and Gildan.

Our in-house experts guide you from start to finish—whether you need help choosing colors, sizing, or artwork format.

We offer competitive pricing and fast turnaround times.

You can easily get a quote online or call us for a quick consultation.

Whether it’s 24 shirts or 2,000, we treat every order with the same level of care and quality control.

Tips for Spot Color Printing Success

To get the most out of your next order, keep these tips in mind:

Use vector art (AI, EPS, or SVG) for best results. If not, a high-res PNG (300 DPI) works too.

Stick to 1–4 colors for affordability and sharpness.

Provide Pantone codes if you have them, especially for logos.

Talk to your printer (hey, that’s us!) about the fabric, ink feel, and finishing options.

Still unsure what’s best? Our team can help you decide whether spot color or another method fits your needs.

FAQs

Q: Can spot color printing be used on non-t-shirt items like hoodies or tote bags?

A: Absolutely. Spot color works great on cotton hoodies, tote bags, and even aprons—just ask us about your product choice.

Q: What’s the difference between spot color and CMYK printing?

A: CMYK blends four inks (cyan, magenta, yellow, black), while spot color uses solid inks for exact shades. Spot color is better for accuracy and vibrancy.

Q: How long does spot color screen printing last?

A: With proper care, the print can last for years without fading, peeling, or cracking.

Q: Do I need to provide the Pantone code?

A: Not necessarily, but it helps. If you don’t have it, we can help match your design to the closest PMS color.

Q: How many shirts should I order to make spot color cost-effective?

A: Typically, 24 or more shirts make the setup fee worth it—but we’ll work with any quantity to fit your budget.

Conclusion: Get Crisp, Consistent Prints with Spot Color

If you care about how your shirt looks—whether it’s your brand logo, school team, or creative merch—spot color screen printing is a proven choice. It gives you bold colors, long-lasting quality, and consistency across every shirt in your batch.

At Tee Vision Printing, we make it easy. Our experienced printers, top-tier materials, and hands-on service ensure you get the results you’re expecting.

Ready to print your next batch of shirts with spot color? Start your order now at TeeVisionPrinting.com