Beginner's Guide to Spot Color Screen Printing

Have you ever considered how those vivid, constant designs on packaging, posters, or t-shirts are created? Spot color screen printing is one increasingly used techniques.

This technique produces exact, crisp drawings using specified colours. This article will break out in an understandable manner what spot color screen printing is, its advantages, and how it is accomplished.

What is Spot Color Screen Printing?

Using premixed inks, sometimes known as spot colours, spot colour screen printing prints specific tones onto various surfaces, including metal, cloth, or paper.

Unlike other techniques whereby colours are produced by stacking various inks, such as cyan, magenta, yellow, and black (CMYK), these colors are especially chosen and combined before printing. Especially for logos and branding materials, spot color printing is fantastic for designs that demand accuracy and brightness.

Benefits of Spot Color Screen Printing

One of the most often used techniques for numerous printing applications, since spot color screen printing offers several benefits. Let's explore some salient features now:

Color Accuracy: Every time you receive the ideal colour, spot colors are blended to precisely match a certain tone. For logos and branding, where colour consistency is absolutely vital, this is significant.

Consistency: Whether you are printing 10 objects or 1,000, spot color guarantees the same vivid color throughout all prints.

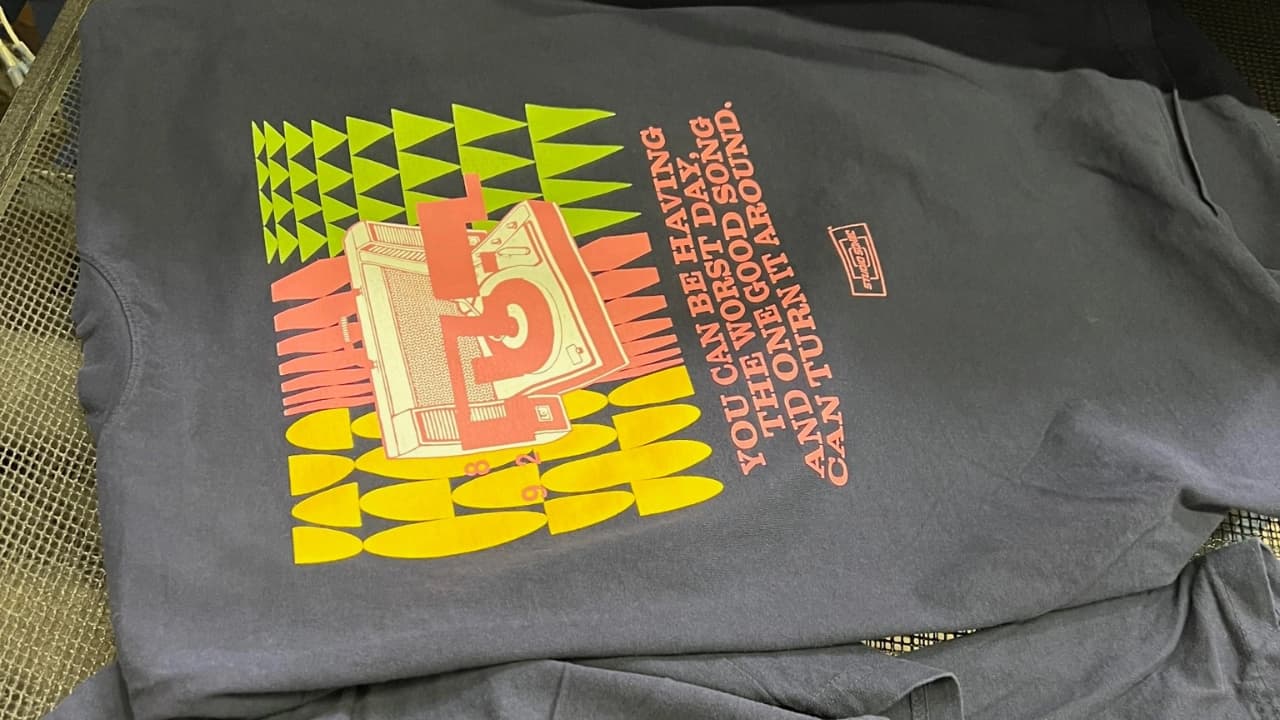

Vibrancy: Spot colors are often far more vivid than colors produced using the CMYK approach, as they are premixed. For brilliant logos or graphics that must stand out, this is especially helpful.

Precise Color Matching: Spot colours let you match brand colors, thereby guaranteeing a consistent look across all your products.

Layered Effects: Your prints will be much more distinctive if you add texture or metallic inks, therefore altering their appearance.

Durability: Spot colour inks are long-lasting, hence even after several washings or environmental exposure, they won't fade or peel readily.

Versatility: This approach works on plastics, metals, textiles, and more, among other materials. You may use it for posters, banners, and even product packaging in addition to t-shirts.

Understanding Spot Colors

Unlike CMYK, which layers colors to produce gradues, spot colors are premixed. The Pantone Matching System (PMS) is among the most often used systems for spot color definition and organization.

Pantone offers a vast range of colors, each with a distinct number that makes it simple for designers and printers to match exactly, wherever in the world. Pantone is the most well-known system; others, such as HKS, are used in Europe.

The Spot Color Screen Printing Process

This is a detailed walk-through of spot colour screen printing near me:

Design Creation: Usually created with tools like Adobe Illustrator, a digital design starts the process. Since every color needs its screen, the design has to be exact.

Color Separation: Every color in the pattern is broken out into several layers. If your design calls for three colors, for instance, it will need three different layers—one for every spot color.

Film Exposure: Once the colors are split, they are projected onto translucent films. Stencils made from these movies are then created on a fine mesh screen covered in a light-sensitive substance.

Screen Preparation: The film is exposed to light and laid on the screen. The light leaves a stencil that ink can pass through by hardening the sections of the screen devoid of design.

Ink Application: Every spot color ink is applied to its designated screen. A squeegee drives the ink across the stencil onto the material.

Curing: Design is cured, or dried, using heat following printing to guarantee the ink bonds effectively to the substrate. This stage guarantees a long-lasting and robust design.

Applications of Spot Color Screen Printing

Spot color screen printing is versatile and can be used in many industries. Here are some examples:

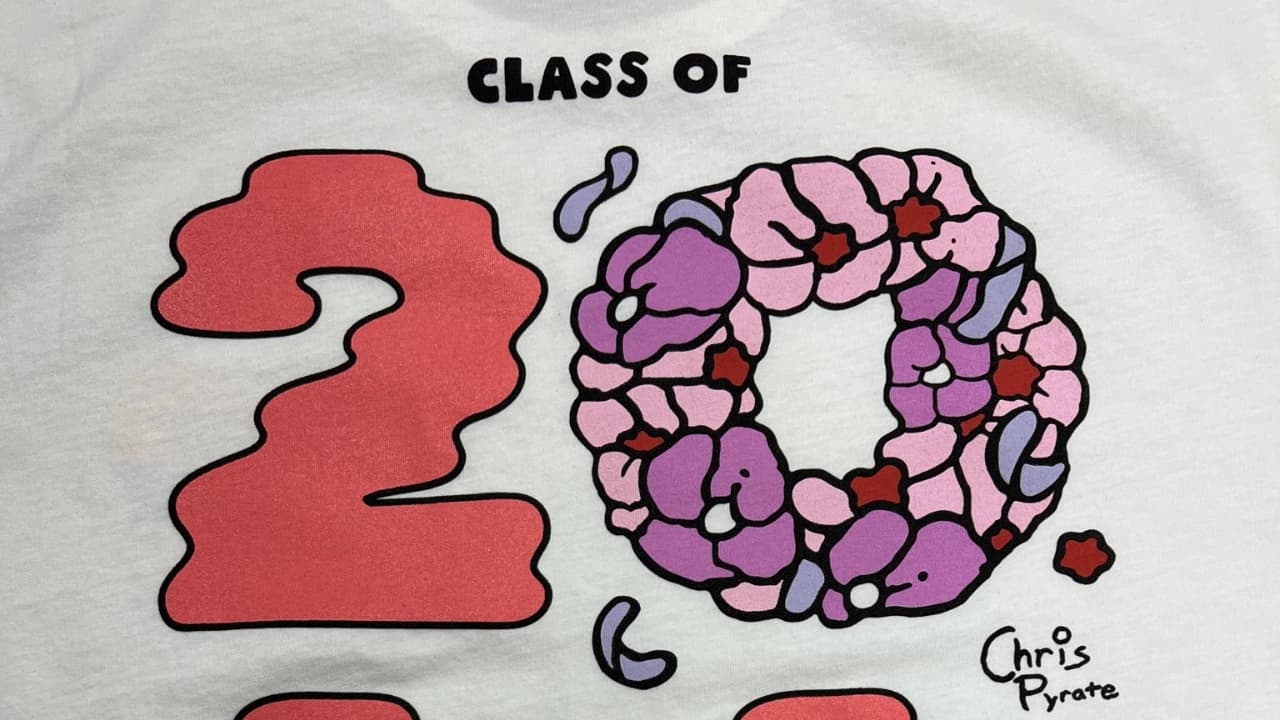

Branding: Many companies build logos and branding materials using spot color screen printing. It guarantees the color of their trademark stays the same on all advertising products.

Packaging: Often used in packaging to highlight a product is spot color. Imagine a strong brand or a distinctive design that catches on the shelves.

Fine Art Prints: Artists utilize this technique to replicate premium reproductions of their work. Fine Art reproductions. For limited-edition prints, it's a fantastic choice with precise colours and durability.

Promotional Materials: Printed with spot colors, T-shirts, posters, and banners with their bright, vivid designs often catch people's attention.

Conclusion

Spot color screen printing is a powerful method known for delivering vivid, consistent, and long-lasting results. Whether you're working on branding, packaging, or promotional merchandise, this technique ensures your designs look sharp and professional every time.

By understanding how the process works and what benefits it offers, you can get the most out of this approach for your printing needs.

Whether you're new to screen printing or looking to level up your current designs, spot color screen printing might be exactly what you need to create bold, high-quality products.

Want professional results that stand out?

Visit Tee Vision Printing to get your custom screen printing done right—vibrant, durable, and made to impress.